Requesting A Call:

At PINAK Global, we have the infrastructure and expertise to design and develop aluminium castings of the most challenging complexities. With trained and qualified personnel with considerable expertise in Pattern Tool And Development & product development, we offer the finest Pattern Tool And Development services in the industry. ALso with our exclusive trade mark technologies we cut our development time for parts delivery

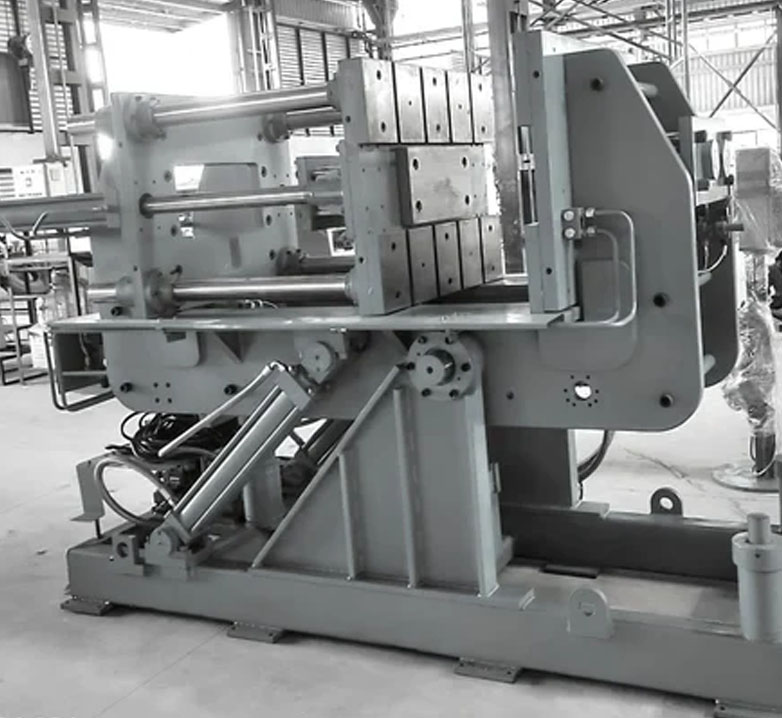

We Pinak Global offers Tilting Gravity Die Casting process which replaces manual workmanship with computable & automated process.

In current genertion of industris industries gears are often needed during new product development to prove the effectiveness of a design. As a custom gear manufacturer, we has the capabilities manufacture prototype gears that adhere to strict customer requirements. When you need to cut short the time development you can feel confident on our prototyping gear manufacturing services for a unique solution.

We PINAK Global, can outsource the Process of ferrous Castings as per All Global Fe & Special Alloys such as material such as Si-Mo etc., as per Standards & Specifications based on Customer Requirements. Materials: GG 200, GG 250, GG 300, GGG40, GGG50, GGG60, GGG70, Si-Mo, and All Equivalent Grades

Features:

Any Intricate Profile with the Minimum Wall Thickness of 2.50 – 3.00 mm.

Any Linear Size of Casting with the Maximum Weight of 400 Kgs per Part for Fe- Iron Castings.

Better Surface Finish and Casting Reliability.

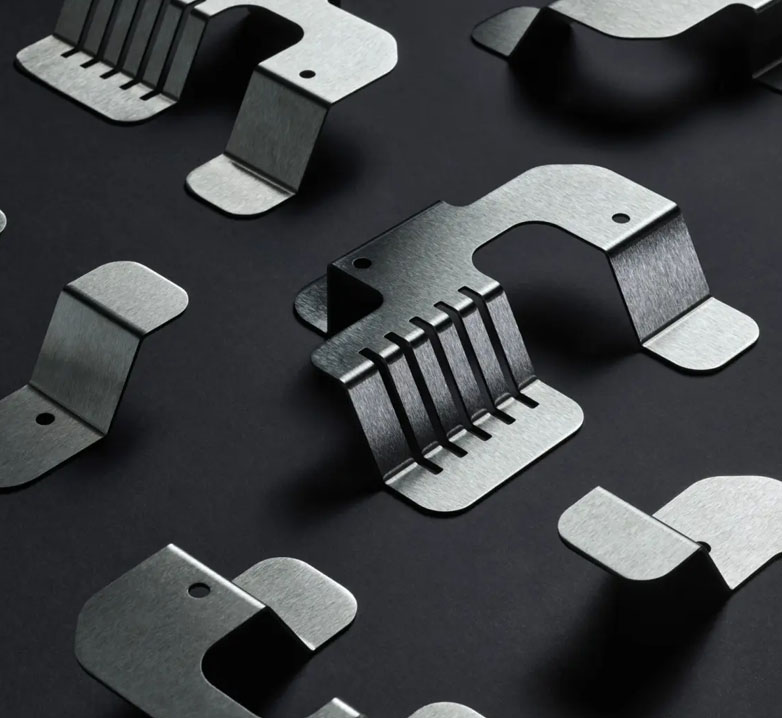

PINAK Global provides sheet metal prototyping services offer a fast and cost-effective solution for your projects. Services including bending, punching, cutting standard gauge metal for both prototypes and low volume production runs. Sheet metal fabrication produces durable, end-use metal parts with a wide selection of materials and finishes that meet your specifications, for a variety of industries like: Automotive, Medical device, Aerospace etc.