Requesting A Call:

Getting to market faster, quicker, better iterations and significantly lower project development costs are benefits that every our customers enjoy. With vacuum casting, our dedicated production teams are able to create complex parts, often incorporating intricate details and undercuts, in a range of materials and sizes to exacting standards. With over 25 years experience, vacuum casting accounts for a large proportion of Pinak’s core business.

With our knowledge and experience of RIM Casting we are able to offer high-precision parts at exceptionally high quality standards for Automotive, Industrial and Electronics applications. This process are recommend for the bigger parts which is Better economic for parts with lower volume when compared to traditional injection molding

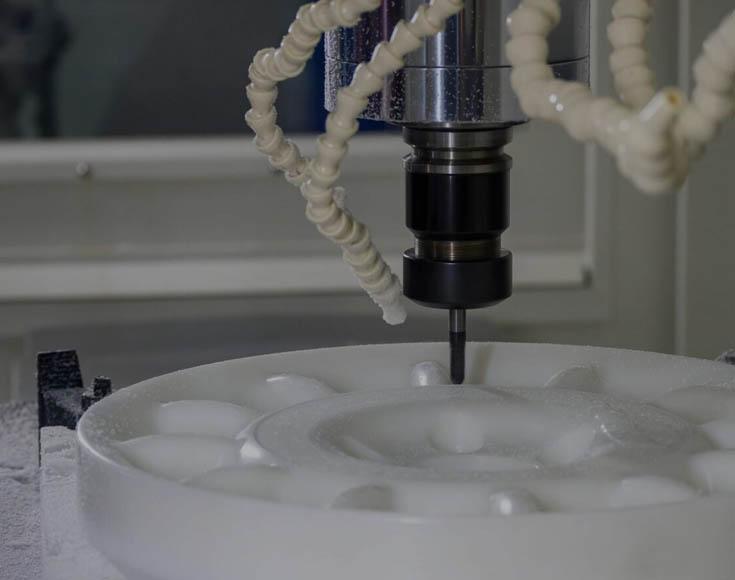

Custom prototypes or machined parts. We can offer the right CNC machining options for your plastic and metal parts and deliver on-demand manufacturing from our , advanced CNC machining service. This is a good option for one of parts where quick turnaround is required.